When I create my own keyboards, I am often provided with only 3D data, saying, “Please print the case yourself.

In general, 3DP printers are still not widely used, and the price is expensive and maintenance is required, so it is still a hurdle for individuals to introduce them.

In such cases, a “3D printing service” comes in handy.

DMM.make is well known in Japan, but its slightly higher price is a problem.

In terms of price, the JLCPCB-affiliated ” JLC3DP ” service, which is well known for ordering circuit boards, is inexpensive, and many people in the homebrew keyboard community are surely using this service.

This article describes the types of print materials that can actually be ordered from JCL3DP and the amount of error that can occur depending on the material.

Please use it as a reference for your order.

Representative of GreenEchoes Studio

He launched his own media as a site operator and web writer, and now plans and manages multiple corporate media. He often types heavily in his work, and in his search for greater efficiency, he became addicted to the keyboard swamp and established “GreenKeys”.

Printed for sample

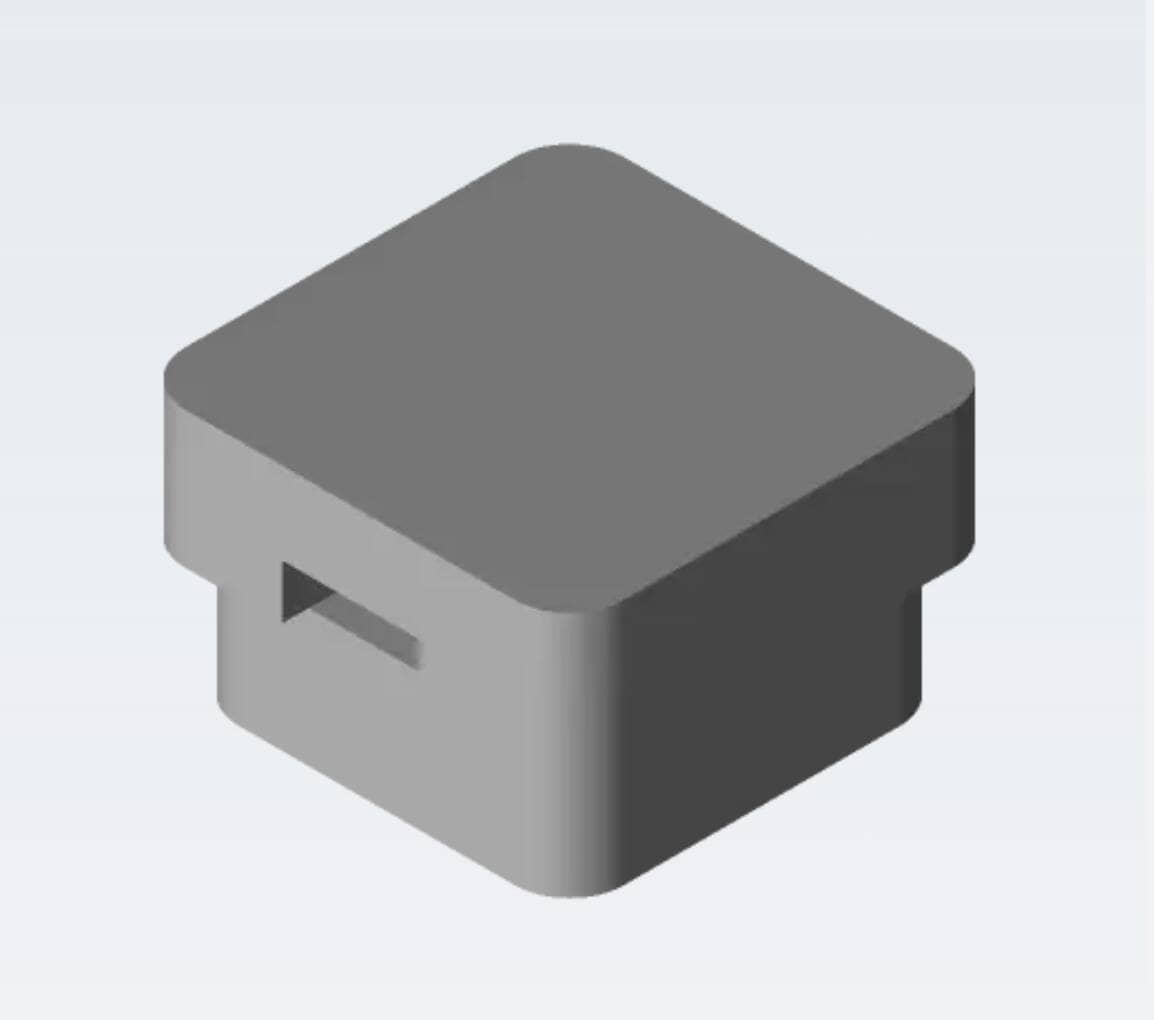

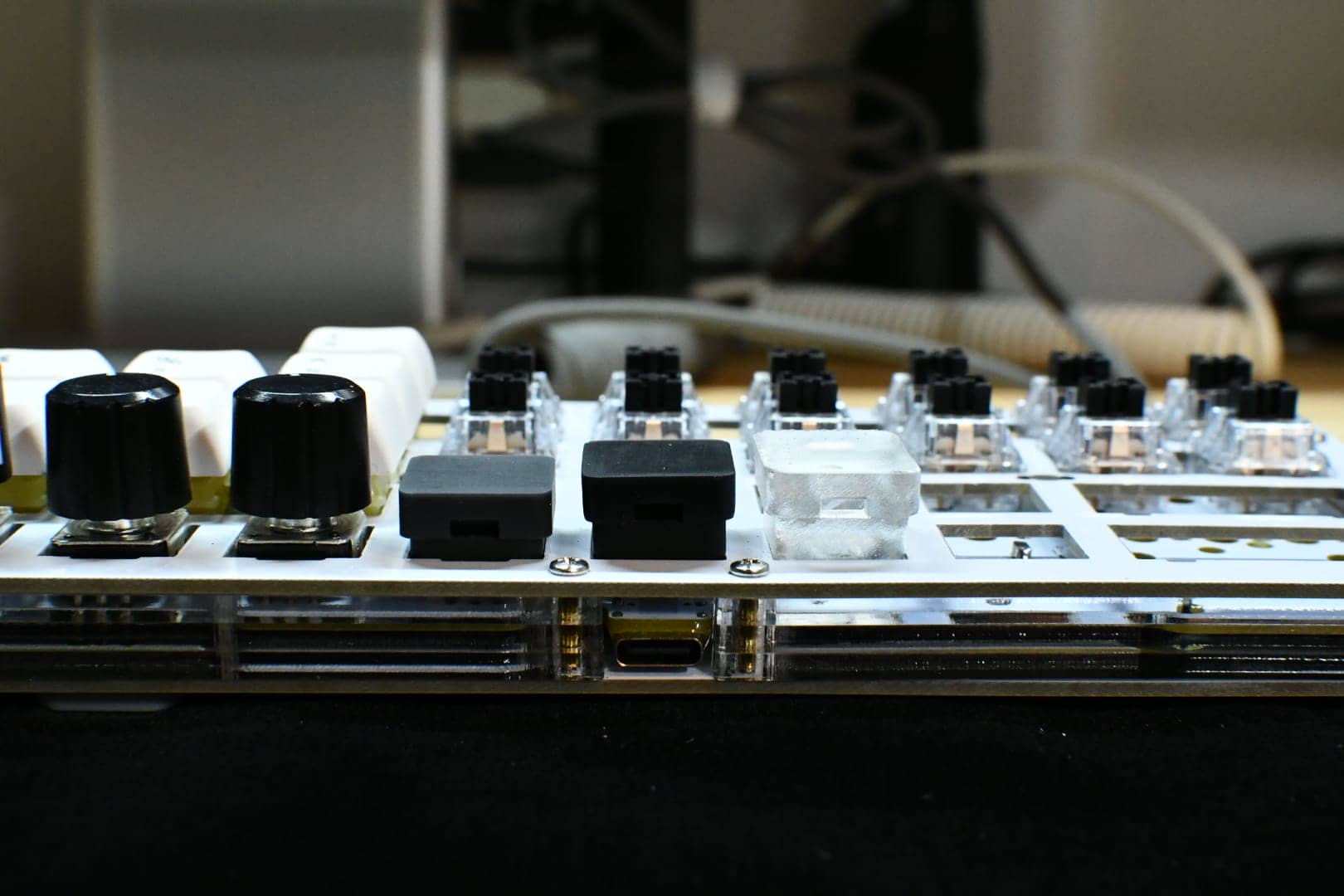

The part we printed this time is called a key switch blocker.

This is used to fill the “holes” in mechanical keyboards that fit switches that conform to the Cherry MX standard to improve their appearance.

This time, we used this data and had it printed in 12 different materials.

Type of print material ordered from JLC3DP

The materials printed this time are as follows

| Stereolithography (Light modeling) SLA | 8001 | transparency translucent | tough Dimensional Stability |

|---|---|---|---|

Ledo 6060 | white | Dimensional Stability Heat resistant | |

9000R | white | Yellow discoloration resistance ◎ Dimensional Stability shrinkage | |

CBY (former Soviet Union intelligency agency) | off-white | Smooth surface Dimensional Stability Heat resistant | |

8228 | cream yellow | Smooth surface Dimensional Stability shrinkage Yellow discoloration resistance ◎ Toughness | |

Black Resin | gray-black | Smooth surface Dimensional Stability shrinkage Yellow discoloration resistance ◎ Toughness | |

8111X | white | Smooth surface Dimensional Stability shrinkage Yellow discoloration resistance ◎ heat-resistant paper | |

Imagine Black | black | Smooth surface Dimensional Stability Humidity Resistance |

| Multi Jet Fusion MJF | PA12 HP Nylon | black | Durability Chemical Resistance ◎ |

|---|---|---|---|

PA12 HP Nylon | gray (SI unit of absorbed dose of radiation) |

| Selective Laser Sintering SLS | 3201 PA-F Nylon | black | Toughness grained texture Printing System |

|---|---|---|---|

Precimid 1172 Pro Nylon | white | Toughness Particulate texture Printing System |

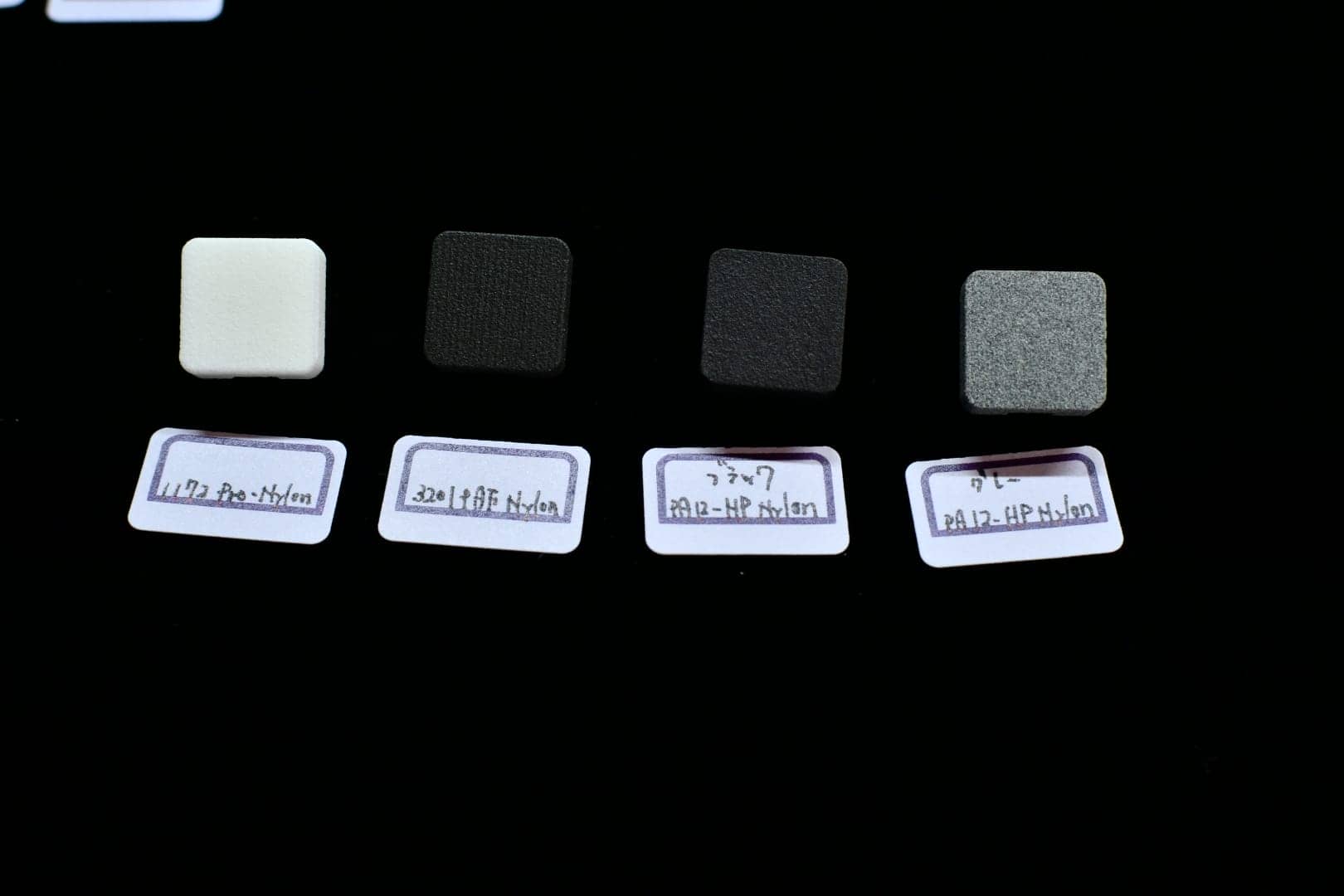

Comparison by color and material

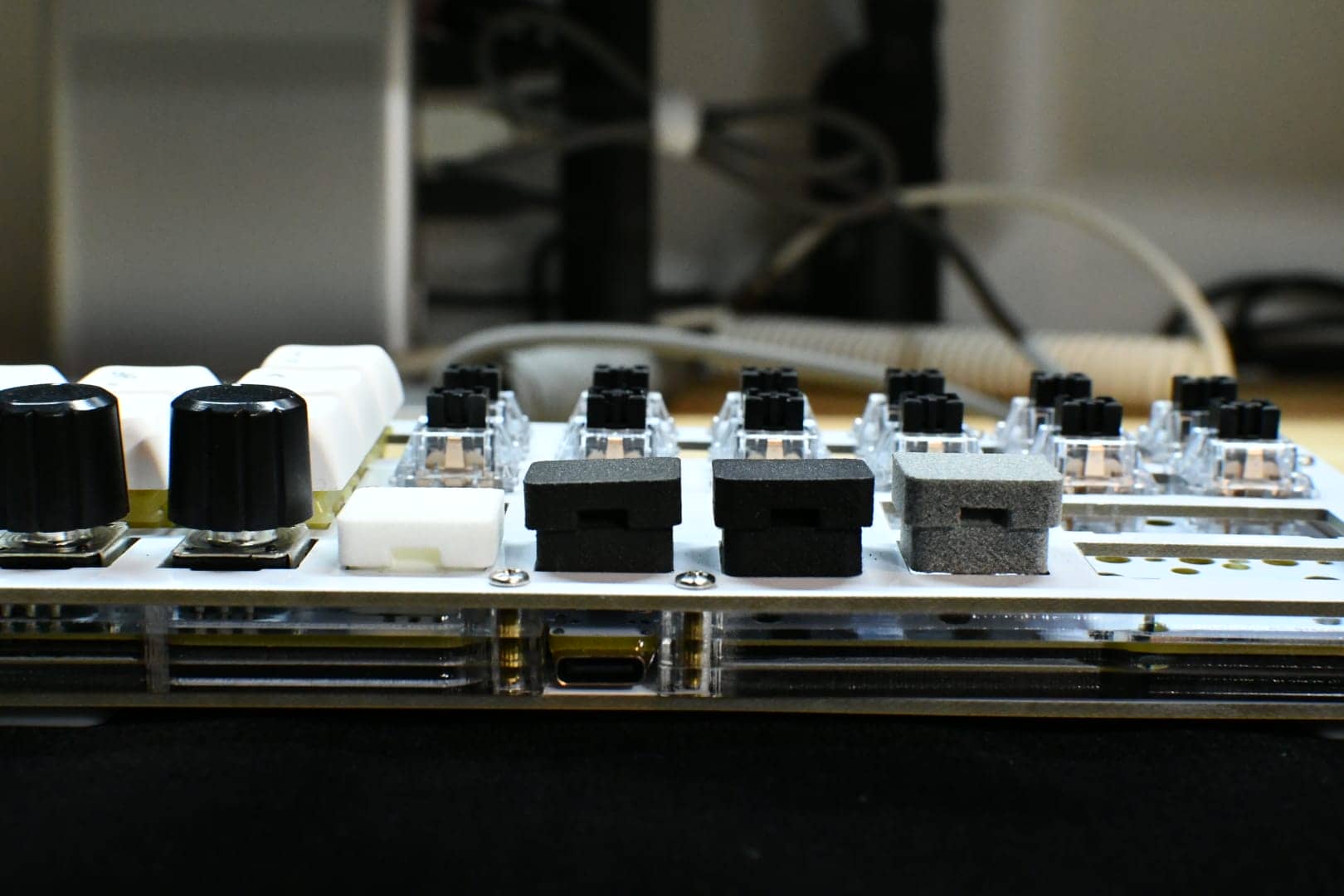

Let’s start with resin black tones.

Thus, black resin is black, but it is a grayish hue, closer to gray than Imagine Black.

On the other hand, as for Imagine Black, it is really black.

The color is not “jet black,” but rather “black” in appearance.

Below is a contrasting image of a keyboard with an Imagine Black case on a “jet black” background for reference.

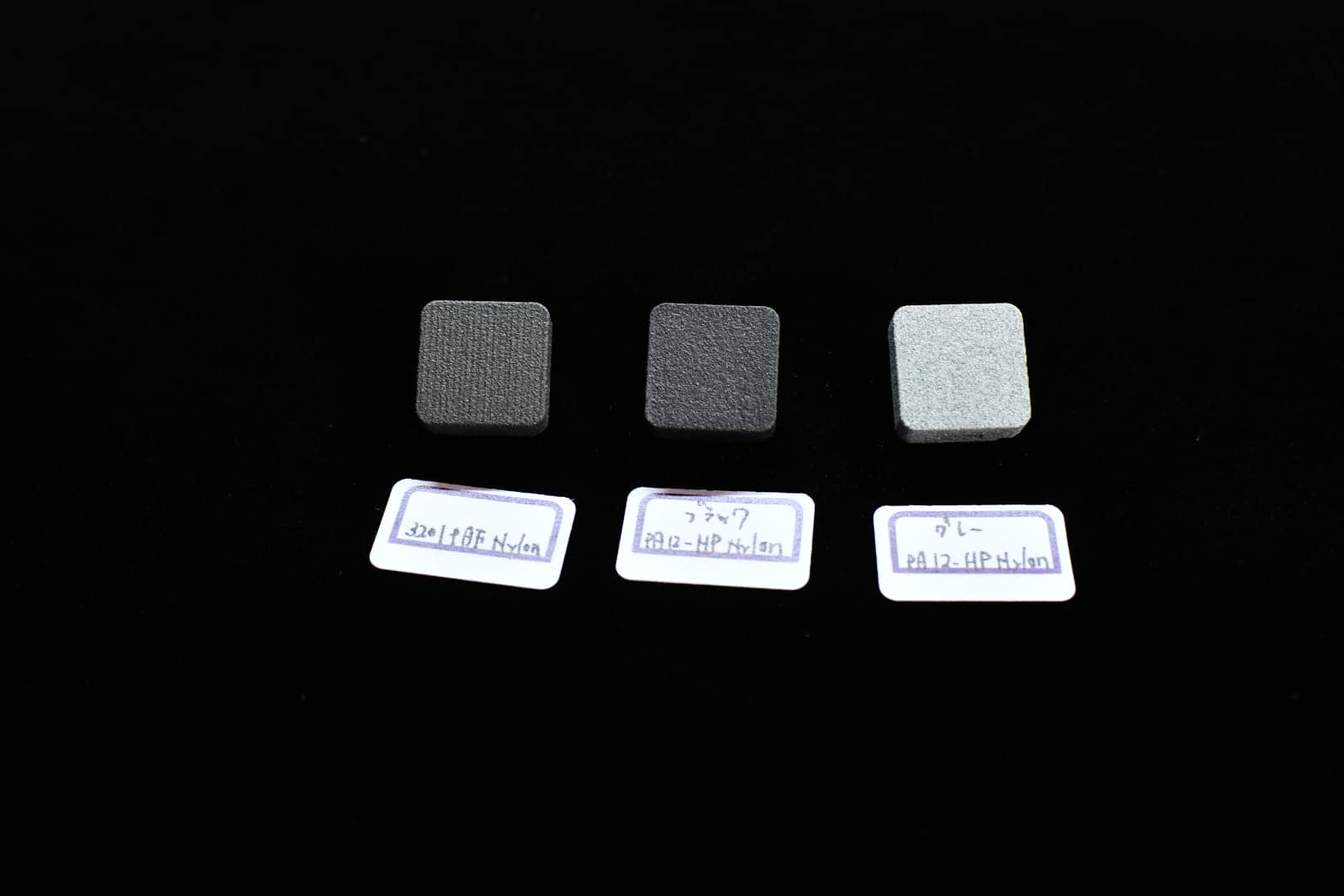

Next is a comparison of nylon black systems.

As you can see, PA12HP nylon (black) is the blackest, while 3201 nylon has a slight gray tinge.

PA12HP gray is a relatively white hue.

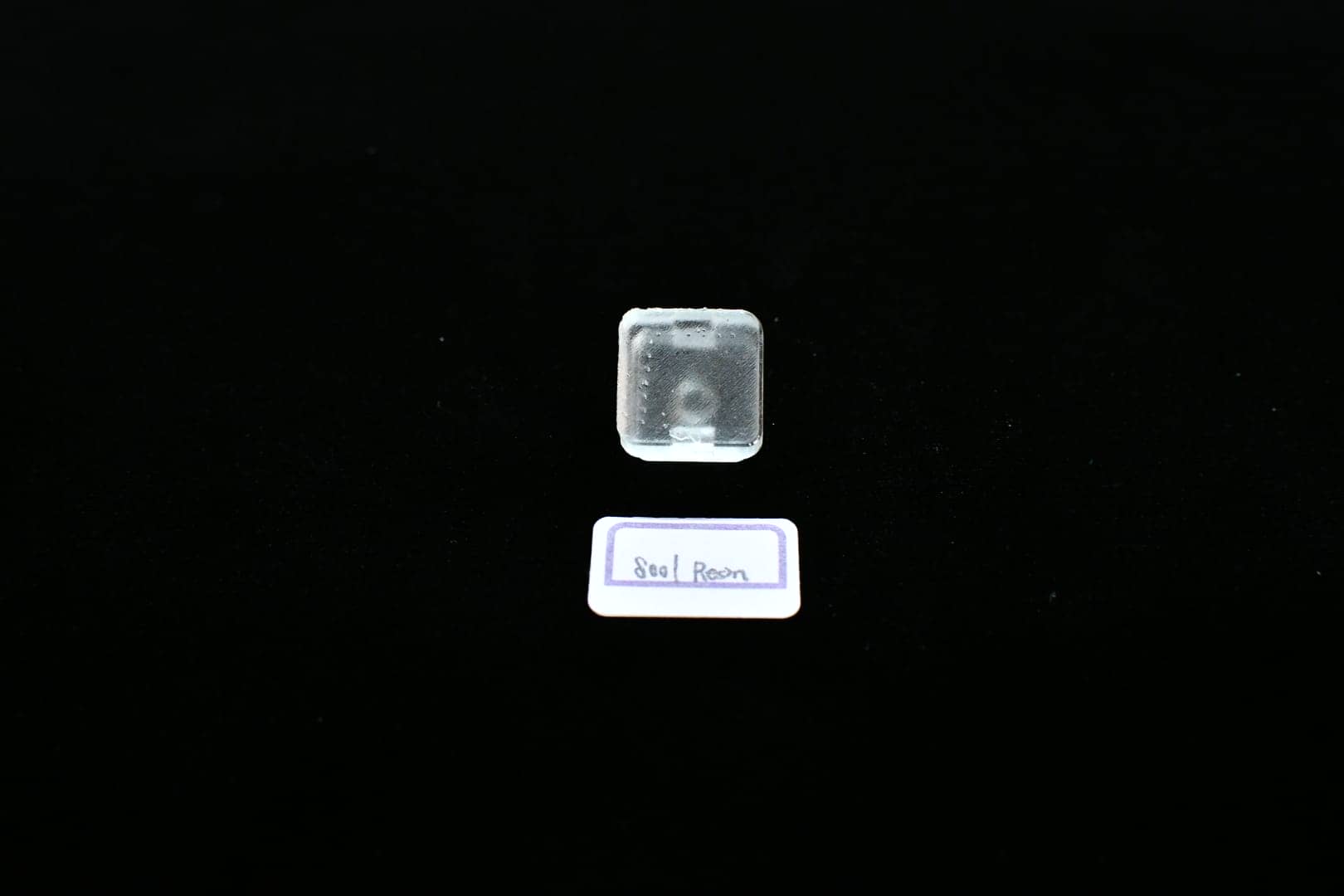

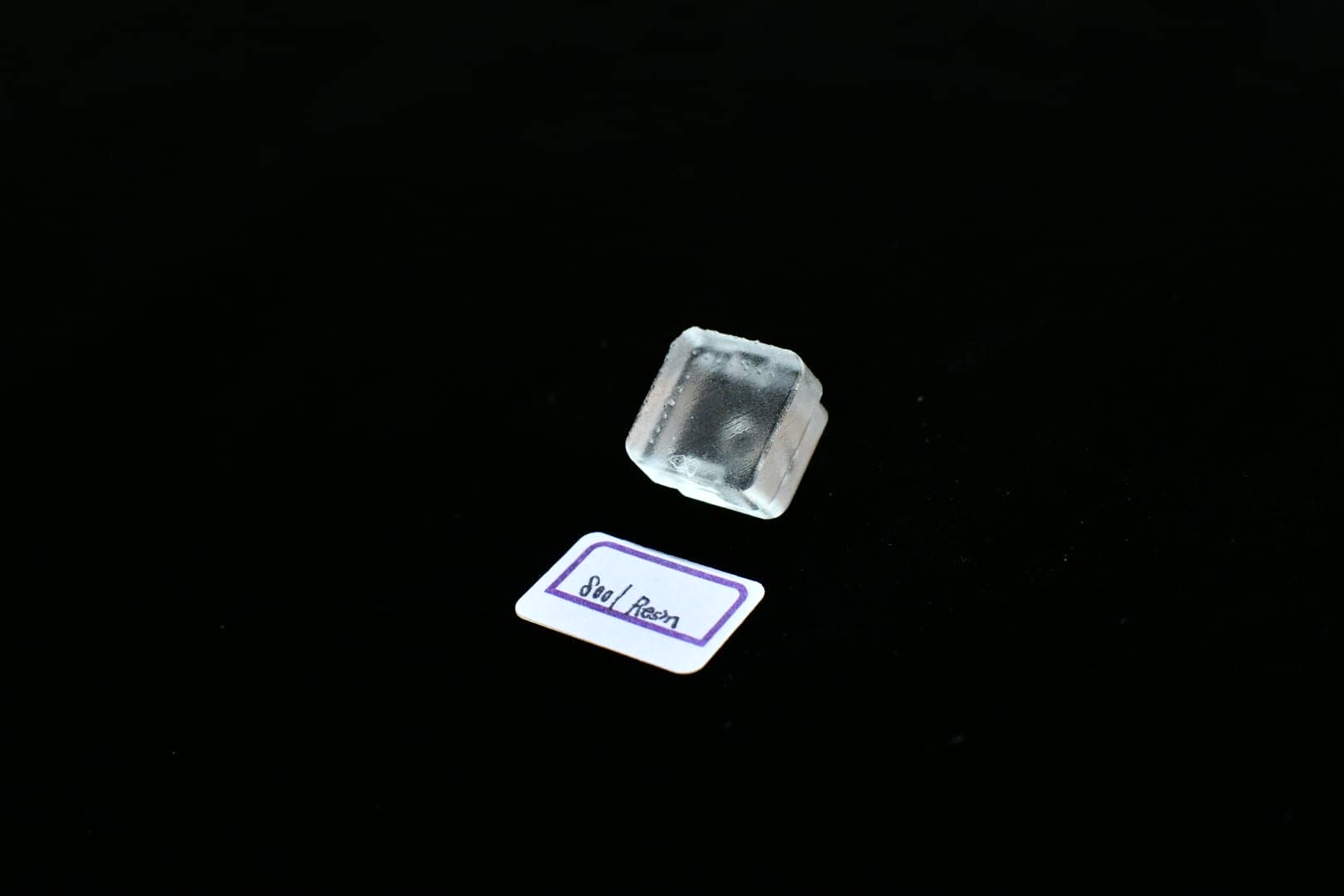

The only transparent material, 8001Resin, was ordered without the “oil spray” option selected.

Thus, air bubbles tend to remain and the surface finish is quite rough and uneven.

Polishing with the included sandpaper will easily flatten the surface, but will result in a misty, cloudy texture, so those seeking transparency should choose the oil spray option.

Please note, however, that selecting the oil spray option will not solve the air bubble problem.

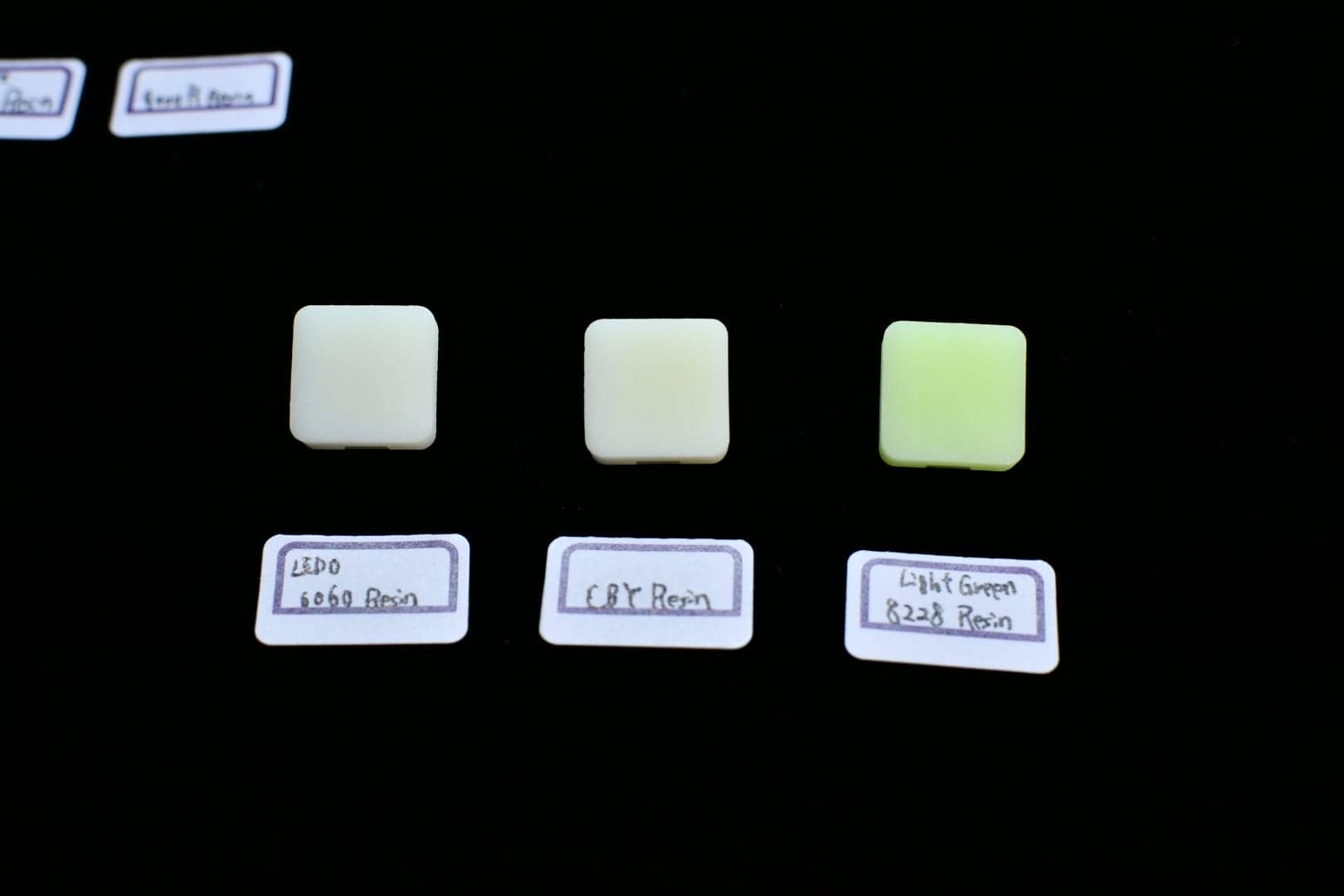

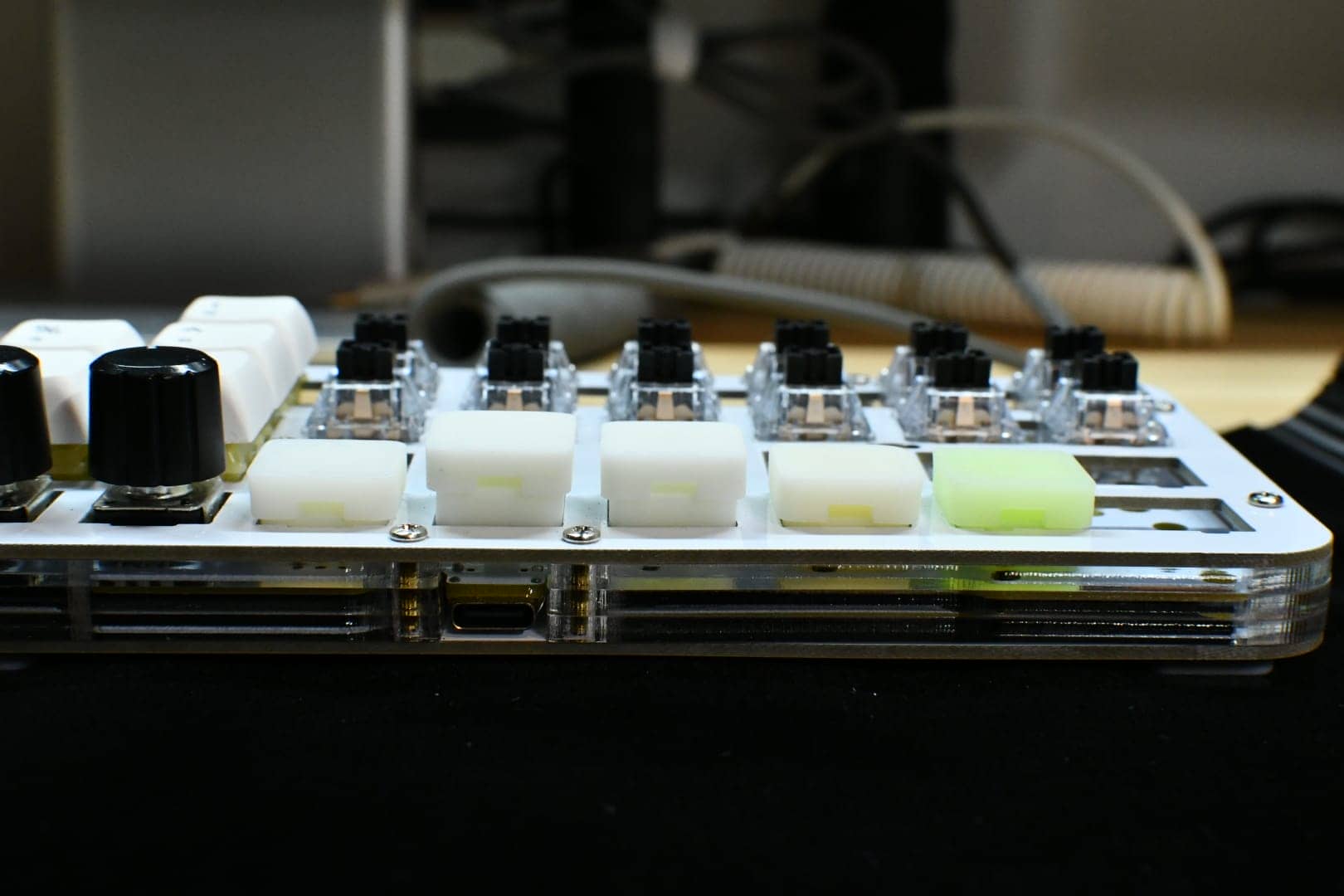

The resin white system is then compared.

There are many types of whites, and the hues of white vary widely.

I am sure you all know that there are 200 kinds of white.

The resinous white closest to yellow is 8228Resin.

From there, the off-white CBYResin, LEDO6060Resin, 8111XResin, and 9000RResin, in that order, approach white.

If you want “pure white,” 9000R Resin is a good choice.

However, if you prefer a nylon material, “1172 Pro-Nylon” is closer to pure white.

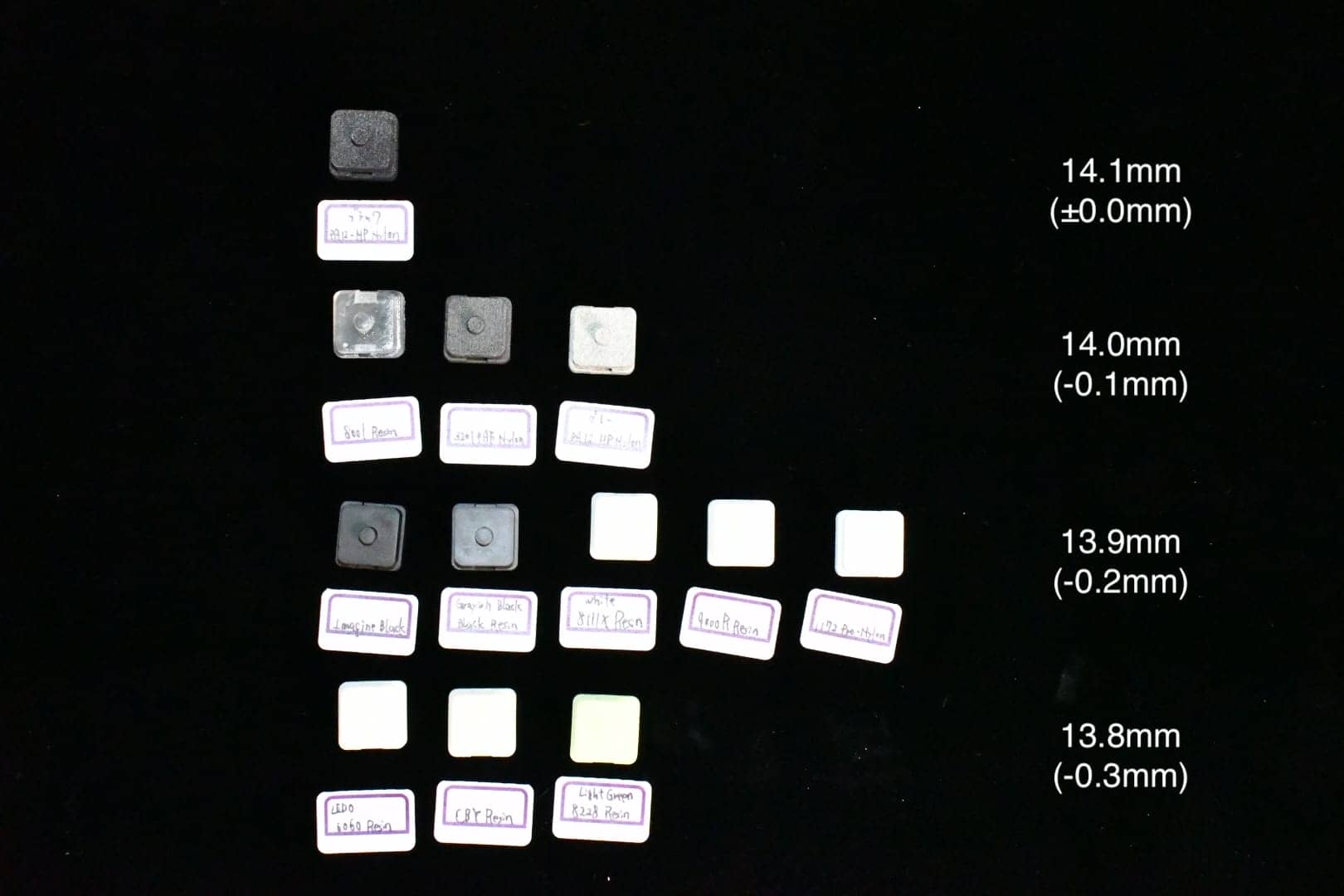

Personal opinion on dimensional stability and shrinkage

The most important thing I wanted to know was how accurately they would reproduce the dimensions.

As a matter of experience, we thought that the “ease of bulking” varies depending on the material, but there is no clear standard value.

Therefore, we have verified how much error there is in the actual printed material compared to the dimensions of the four sides (14.1mm✖️14.1mm) that are fitted into the plate of the key switch blocker.

The results are shown below.

| PA12 HP Nylon(Black) | 14.1mm | ±0.0mm |

|---|---|---|

| 8001/PA12 HP Nylon(Gray)/3201PAF Nylon | 14.0mm | -0.1mm |

| BlackResin/Imagine Black/8111X/9000R/1172 Pro Nylon | 13.9mm | -0.2mm |

| LEDO6006/CBY/8228 | 13.8mm | -0.3mm |

Contrary to my expectations, not a single one was bulging; in fact, most of them were smaller.

The hole per side of the MX compatible switch plate is about 14mm, and I thought that all of them would fit in the hole for a smaller size like this one…but they pretty much didn’t.

It seems to vary depending on how much it deforms (≒hardness) when pushed in and how slippery it is.

As for the misalignment of screw holes caused by 3D printing, it may be correct to think that the misalignment is not due to expansion, but due to contraction.

summary

- Black color intensity|ImagineBlack > 3201PAF Nylon > PA12HP Nylon(BK) > Black Resin > PA12HP Nylon(GR)

- Proximity to pure white|1172Pro Nylon > 9000R > 8111X > LEDO6060 > CBY > 8228

- Most excellent|PA12 HP Nylon(Black)

- Slightly superior|8001/PA12 HP Nylon(Gray)/3201PAF Nylon

- BlackResin/Imagine Black/8111X/9000R/1172 Pro Nylon

- Slightly larger shrinkage|LEDO6006/CBY/8228

This is the result of my experiment, but this may not be the case depending on the shape to be printed.

Please keep this as a reference only.

To order, please click below.